FP300Series

Converter for Pneumatic Signal

FP300 Series converters transform a digital signal into a pressure signal. They act as an interface to a system FP302 - Foundation™ Fieldbus Models or FP303 - PROFIBUS PA Models, such as a pneumatic actuator or with a valve positioner.

- The FP300 is based on the principle of the pneumatic relay and the nozzle-vane assembly. When the control system requests an increase or decrease in output pressure, the vane, made of piezoelectric material, moves closer or further away from the nozzle.

- This movement results in a pressure modulation in the pneumatic relay block, changing the output pressure of the FP300. Pressure sensors measure the output pressure and feed back the control circuit, which acts correctly until the desired output pressure is reached.

- The FP300 converter is powered by the FOUNDATION™ fieldbus or PROFIBUS PA signal transmission line.

- The FP300 has a non-volatile internal memory and in case of power failure important data is stored, such as calibration, configuration, identification, etc.

- The FP300 features local adjustment and configuration through a magnetic tool, without any external electrical or mechanical contact, without the need to open the electronic housing cover, which guarantees its suitability for applications in hazardous areas.

- Additionally, the FP300 can be remotely configured by devices using the FOUNDATION™ fieldbus or PROFIBUS PA communication protocol.

Characteristics

The FP300 Series provides a pneumatic output signal proportional to an input received from a FOUNDATION™ fieldbus or PROFIBUS PA network.

The technology used in the FP300 Series allows easy interfacing between the field and the control room, in addition to providing various types of data transfer, considerably reducing the costs of installation, start-up, operation and maintenance of industrial processes. The concept of function blocks was introduced to make programming easy for the user, who can now easily build and visualize complex control strategies.

Another added advantage is the flexibility of interlocking blocks, as the control strategy can be changed without wiring changes or any hardware modifications. The FP300 Series is offered for output pressures ranging from 3 to 15 psi, or an extended range version from 3 to 30 psi that is user-configurable.

In addition to local configuration, the FP300 Series can be remotely configured through applications that meet FOUNDATION™ fieldbus or PROFIBUS PA standards. Smar provides its customers with applications for both communication protocols for applications where pneumatic actuators are essential or in plants that are in the process of migrating from pneumatic to digital technology. The FP300 Series is designed for installation to IP66 weather and has been submitted and approved for hazardous area applications whether explosion proof or intrinsically safe.

- Two technology options: FOUNDATION™ fieldbus or PROFIBUS;

- Produces an output of 3 to 15 psi or 3 to 30 psi;

- Allows field calibration for 3 to 15 psi or 3 to 30 psi output;

- Configurable local adjustment;

- Ability to interconnect various equipment;

- Allows great flexibility in the implementation of control strategies;

- Indicated for implementation in small and large systems;

- Input: Digital signals according to FOUNDATION™ fieldbus or PROFIBUS PA protocol;

- Output: 3-15 psi (0.2-1.0 kg/cm²) or 3-30 psi (0.2-2.1 kg/cm²);

- Output Capacity: 6.7 Nm³/h (4 scfm);

- Accuracy: 0.4% of span;

- 9-32 Vdc bus power supply;

- Consumption: Quiescent 12 mA.

FP302 - Foundation™ Fieldbus Models

- Their characteristic is the ability to behave like a master on the network;

- 9 types of Function Blocks for control strategies and advanced diagnostics;

- The control strategy can be changed without wiring changes or any hardware modifications;

- Connectivity via PC, local or remote network;

- Local configuration with magnetic tool or portable configurator;

- 12 mA consumption current;

- Dynamic instantiation of blocks;

- FOUNDATION™ fieldbus ITK compliant DD;

- Meets the PROFIBUS DP-V1 version;

- It has built-in function blocks such as: analog output, transducer blocks and display;

- Configuration via:

- magnetic tool - basic configuration;

- remote configurator - complete configuration (eg ProfibusView from Smar or Simatic PDM from Siemens).

- Functional blocks;

- Current consumption of 12 mA;

- Supports DTM and EDDL.

Diagnostics and Parameterization

The complete configuration is done through Smar application programs or applications and configurators from other manufacturers.

Additionally, Smar developed the AssetView application, a tool in web format, with a friendly interface that can be accessed from anywhere and at any time, using an Internet browser. It also incorporates FDT/DTM facilities at no additional cost. AssetView is designed for field device management, with positive impacts on corrective, preventive, predictive and proactive maintenance.

- FP302

- FP303

The FP302 uses the H1 communication protocol, an open technology that allows any H1-enabled configuration tool to configure this equipment. Syscon (System Configurator Tool) from Smar is the recommended software to configure, operate and maintain field equipment, although, because it is interoperable, the FP302 communicates with applications that follow the FOUNDATION™ fieldbus standard.

Syscon provides efficient and user-friendly interaction using Windows Server 2016, Windows Server 2012 R2, Windows Server 2008 R2 SP2, Windows 10 Professional, Windows 7 Professional and Windows 7 Ultimate.

Configuration tools such as AMS™, FieldCare™ and HHT375 can easily configure FP302 devices. DD (Device Description) and CF (Capability File) files can be downloaded from the Smar website or the Fieldbus FOUNDATION™ at no cost.

FP302 supports complex configuration strategies due to the high capacity and variety of instantiable function blocks. Nine types of function blocks are available. Fieldbus technology allows AssetView to access status and diagnostic information from the FP302. In this way, maintenance procedures become more effective, providing greater safety and plant availability.

The FP303 was designed to use the PROFIBUS PA protocol and can be configured using Simatic PDM and the FDT (Field Device Tool) and DTM (Device Type Manager) tool concepts, such as FieldCare™ and PACTware™. It can also be configured by any PROFIBUS system using the GSD (Generic Station Description) file.

PROFIBUS PA also presents quality and diagnostic information, improving plant management and maintenance.

The EDDL (Electronic Device Description Language) and DTM files are available on the Smar website.

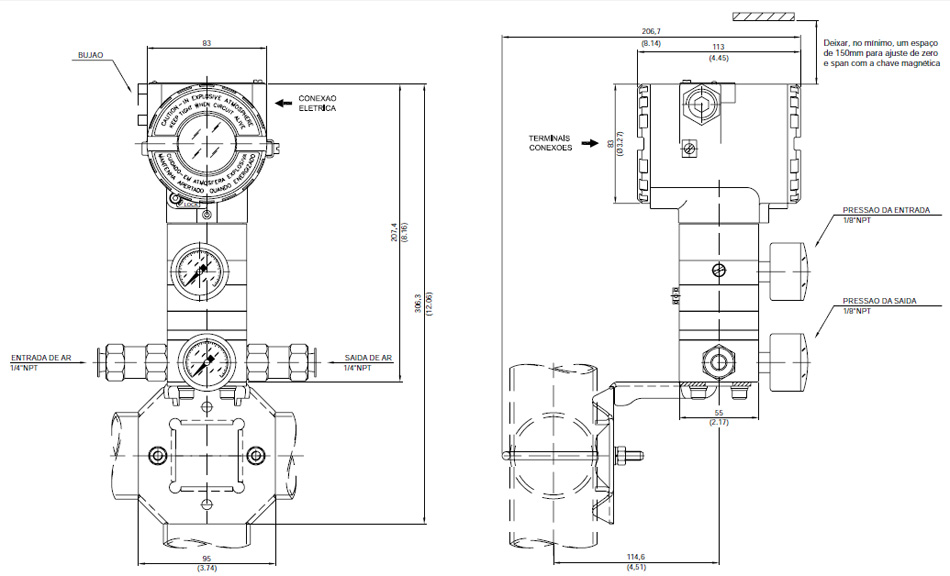

Dimensional Drawing

FP300 - Dimensional Drawing