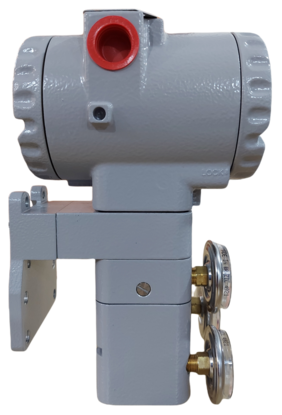

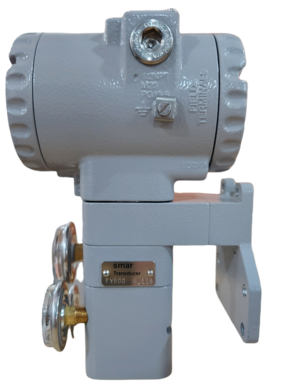

FY500Series

Intelligent Valve Positioner

Functional Description

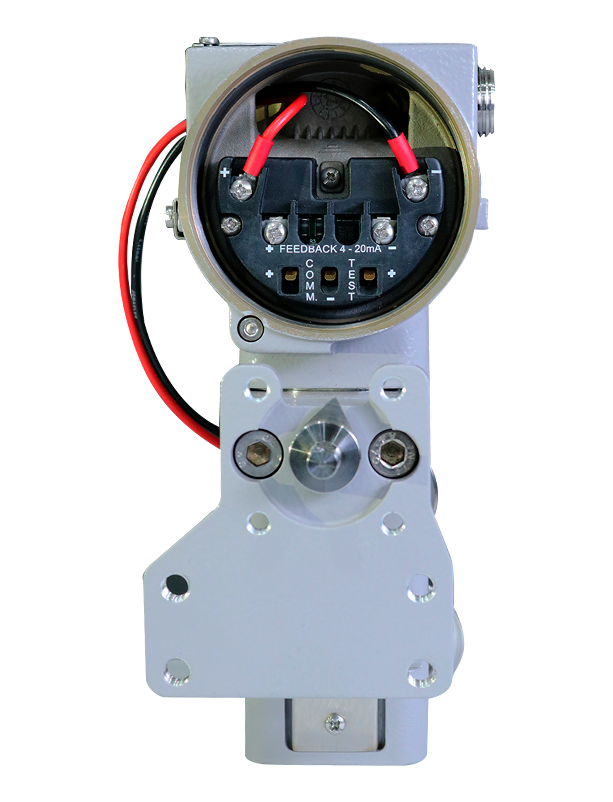

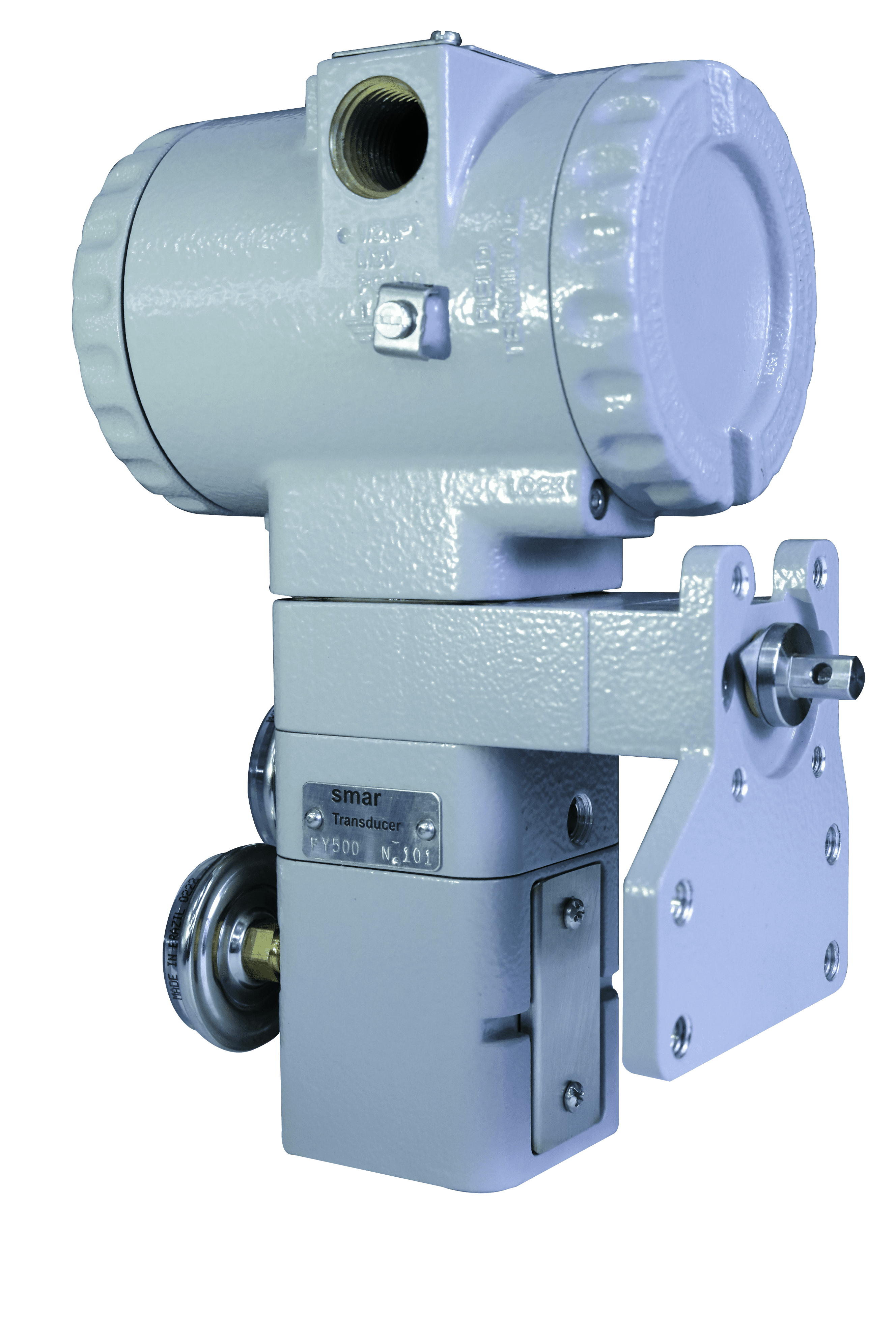

The FY500 is a nozzle-reed system positioner with coil. Accepts a setpoint signal from a controller or other device through a twisted pair of wires.

After executing auto calibration procedure, it compares this input signal to the actual valve position, which it measures with the Hall Effect sensor that is connected to the feedback module.

The difference between the setpoint and the actual position is then amplified and a corrective current signal is sent to the I/P converter module .

The supply pressure to the FY500 passes through an internal pressure regulator that regulates it to approximately 22 psi. The air then goes through an orifice that restricts the flow and air consumption.

The I/P converts the current signal to a pneumatic signal, which is sent to the diaphragm module and the spool valve.

The spool valve directs supply air to the actuator to move the valve until the Hall Effect Sensor reading agrees with the setpoint.

Characteristics

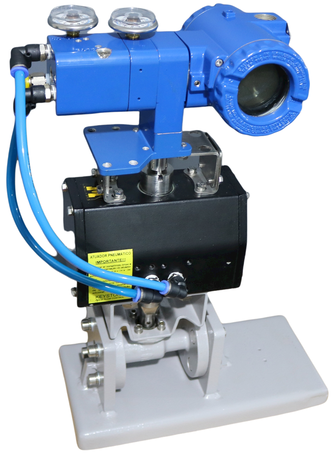

- Mounting on linear actuators according IEC 60534-6, stroke from 12 mm to 200 mm;

- Mounting on rotary actuators according VDI/VDE 3845, NAMUR, from 30° to 120°;

- Auto tune procedure, automatic adjustment of control parameters and valve range;

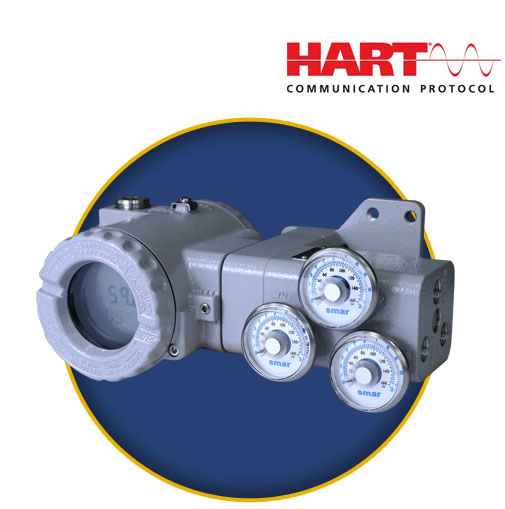

- Local operation and configuration of the device using magnet tool and LCD interface;

- User-friendly rotative display;

- HART® configurable;

- FDT/DTM capability and connectivity;

- Supply pressure up to 10 bar (150 psi);

- The spool valve high volume output with minimal steady-state air consumption;

- Buit-in position feedback provides a 4-20 mA signal for position verification;

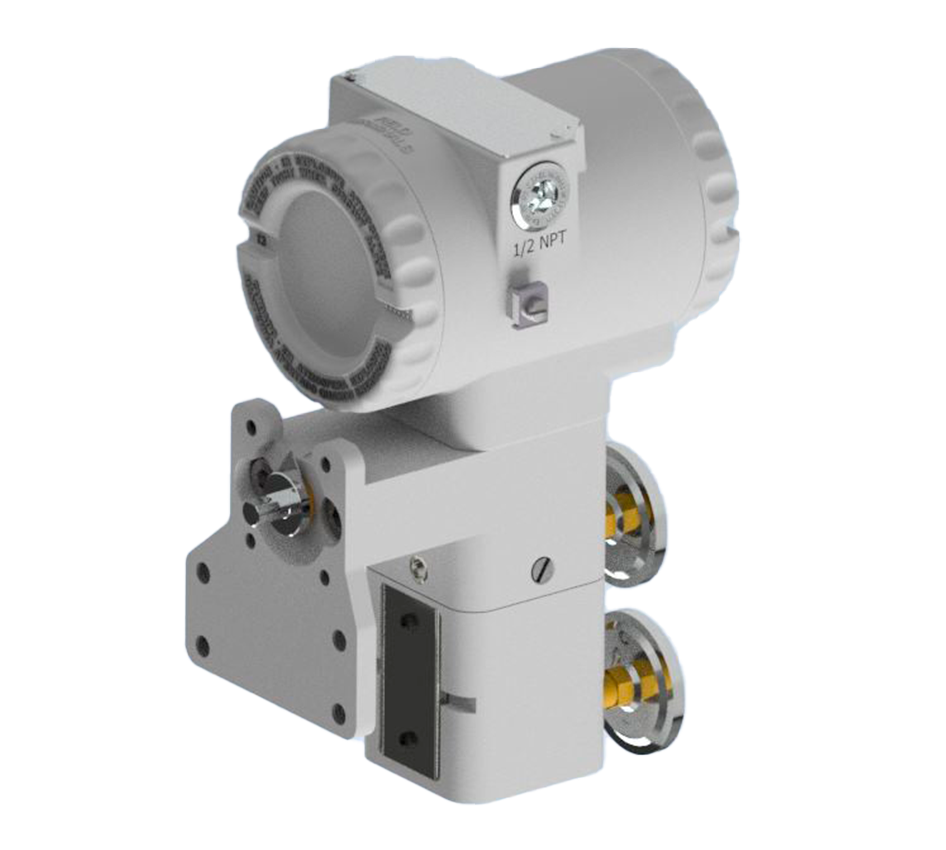

- Optional modular design with two limit switches allows reliable position feedback;

- Design to meet Explosion Proof, Intrinsic Safety, European ATEX directive.

(Certification Pending)

HART® - 4 a 20 mA

- Local adjustment with magnetic tool without needing to open the housing;

- DEVCOMDROID (Android DDL Interpreter) software, used with HART interfaces;

- Remote Parameterization and automatic setup;

- FDT/DTM (Field Device Tool / Device Type Manager) capability and connectivity;

- Multidrop operation mode.

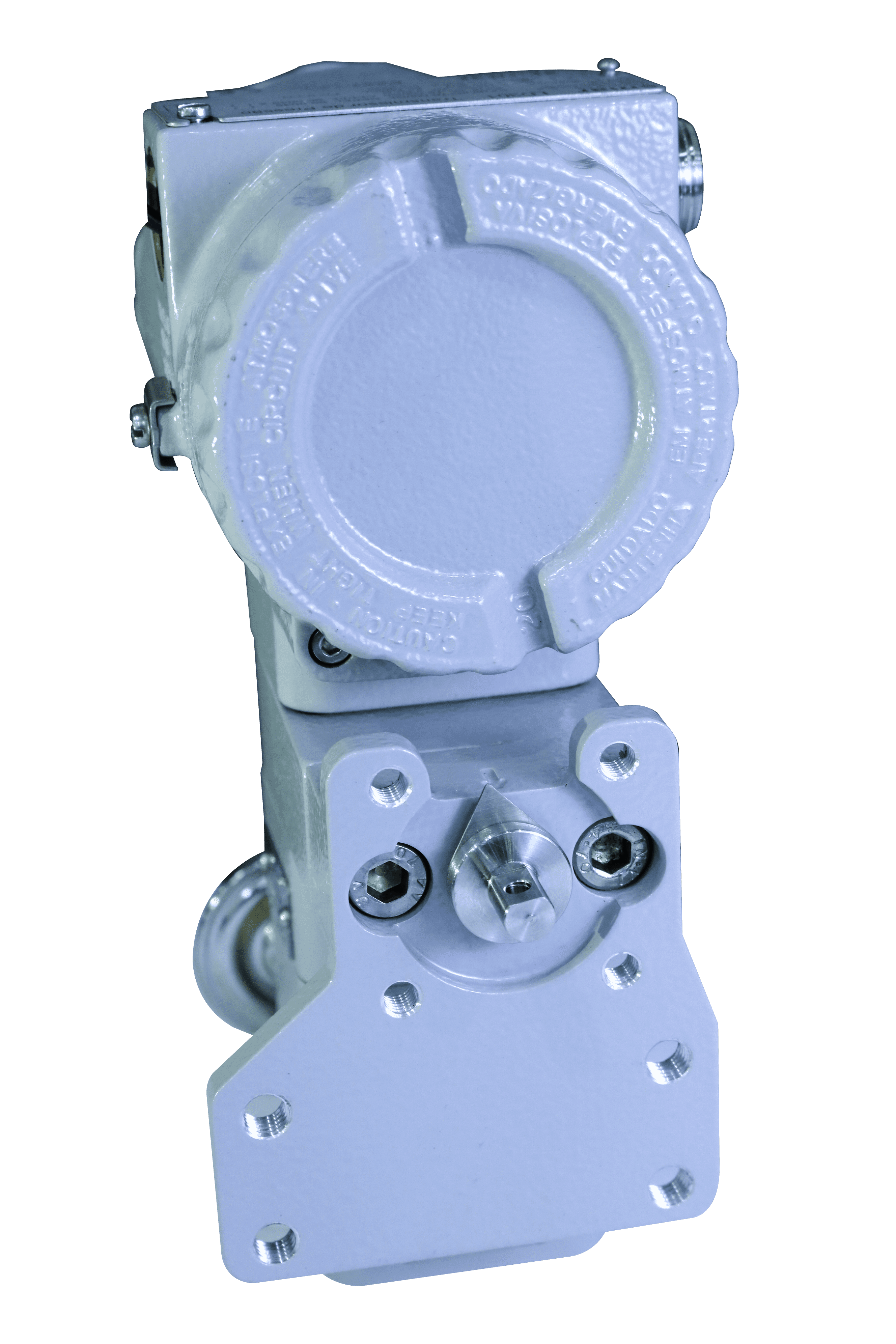

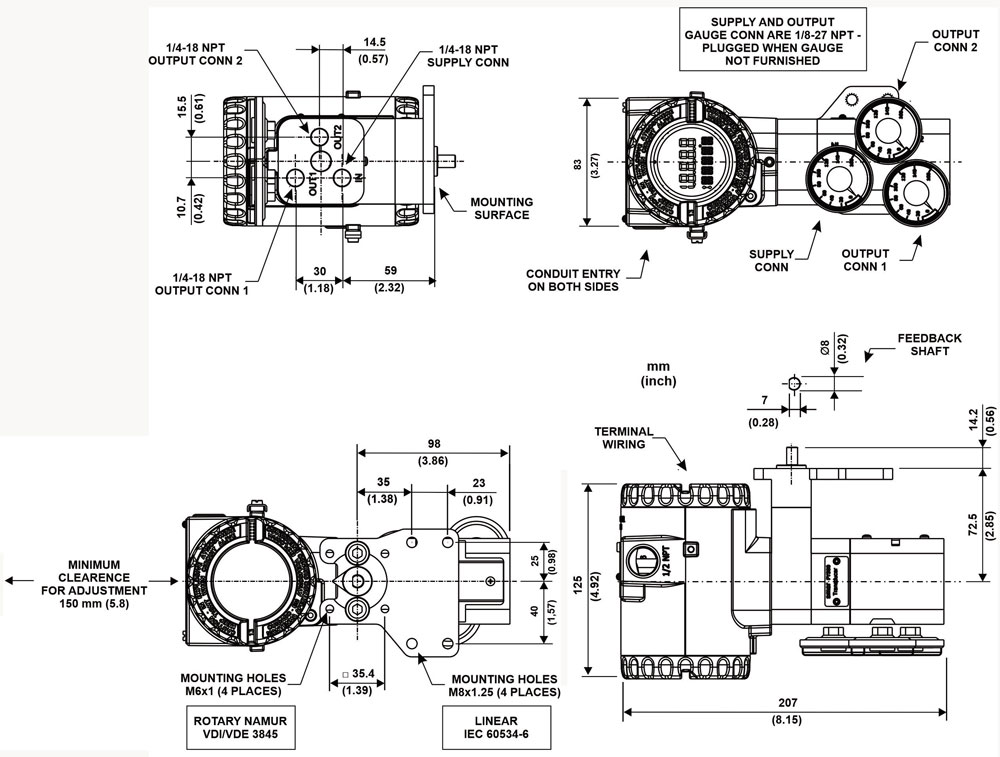

Dimensional Drawings

.jpg)