Open Process Automation Standard

.jpg)

In recent years, IT has produced major technological advances in the area of cyber security, the Internet of Things (IloT), cloud computing, augmented reality, big data processing and analysis.

In the software production sector, there is an expansion of the availability of free software supported by a growing number of devices around the world. We are living the era of the virtual world, the software has emulated the functions that were previously performed by hardware, which simulates the entire operation of a real industrial plant using only one computer, which may be remote, and running in the computational clouds.

The incorporation of these technologies in the industrial sector is known in the market as the digital transformation of the companies towards the Industry 4.0. In this direction, one of the biggest industry requirements is cyber security in order to protect their assets.

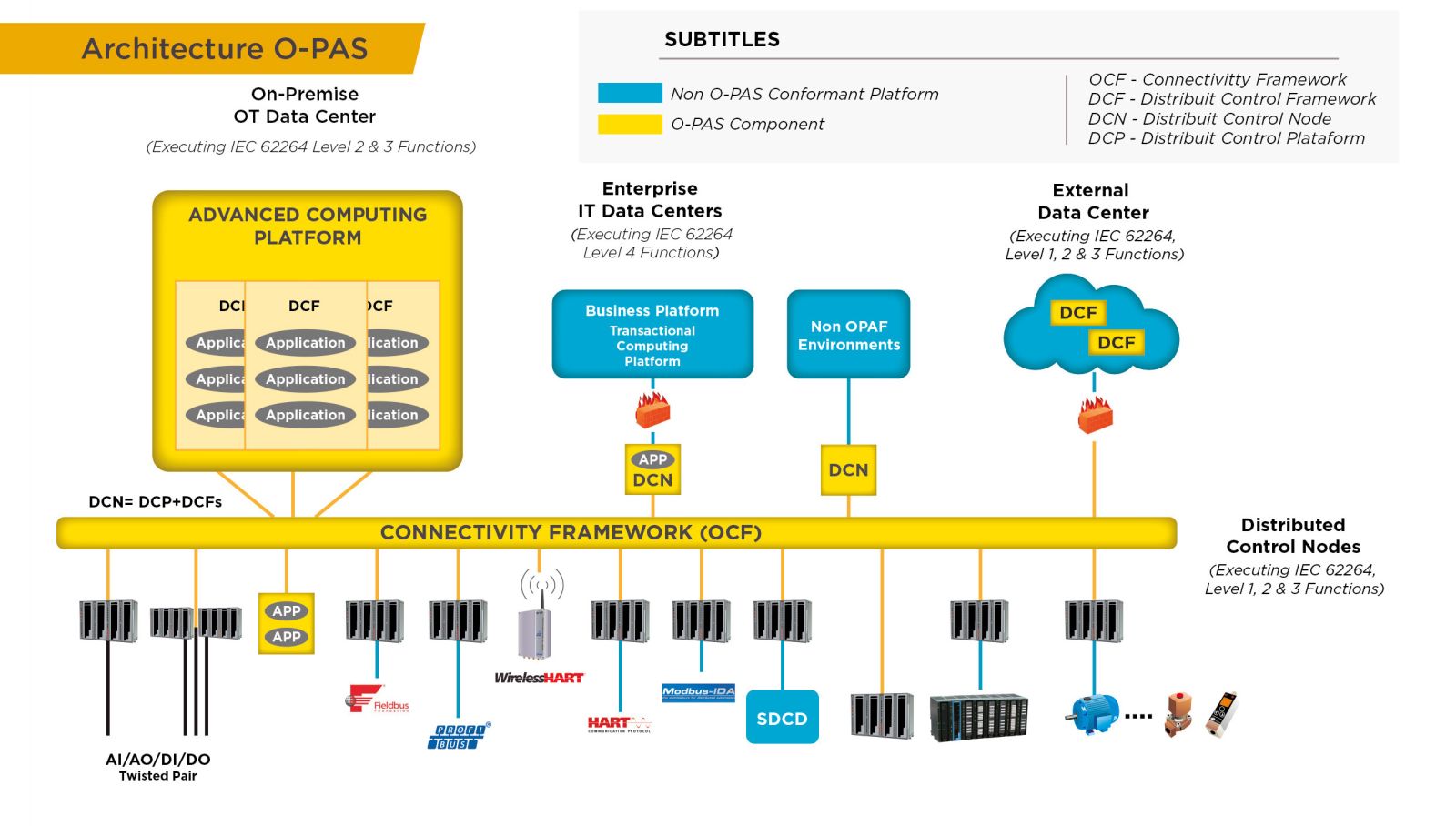

In order to combine the greatest features of process automation control systems to fit in a new digital format, the O-PAS (Open Process Automation Forum) has defined a new architecture for standards-based, open, secure and interoperable automation systems.

The real challenges faced by users in the Chemical, Petrochemical, Oil & Gas, Mining, Steel, Food & Beverage, Pharmaceuticals, Pulp & Paper, Utilities, etc. sectors are covered by the O-PAS standards that aims to join the best-in-class features available in the market into the same common system architecture.

The design and implementation of the next generation process control framework will be based on open architectural standards that will ensure cyber security, modularity, interoperability, extensibility, reuse, portability, and scalability of the new system.

Why do end users want open systems?

- Reduced business costs

- Freedom of choice due to the greater number of suppliers

- Interoperability

- Allows integration of the best components of each category

- Common Computer (IT) Environment

- Applies to various sectors

- Economic insertion of new features through the use of standard hardware and software interfaces

- Freedom to work with local partners in the development of common tools

- Robustness and agility in reusing software and hardware components

- Reduces long-term obsolescence impacts

- Allows requirements for future operating environments to be met

The main element of this architecture is the Distributed Control Node (DCN), a distributed control unit that provides configurable input and output of the process, as wall as acts on regulatory control, digitizes the signals and communicates them to the industry-standard protocols and, in units that support digital field networks, acts as a communications network manager. The Association of the signals is done via software (tag) and not by physical connection ( addresses and tables ).

Smar is actively participating in O-PAS definition and validation activities. The System302 architecture, provided by the Smar brand since 2002, is fully compliant with the architecture proposed by O-PAS and the company is committed to incorporating the new software requirements defined by the forum.

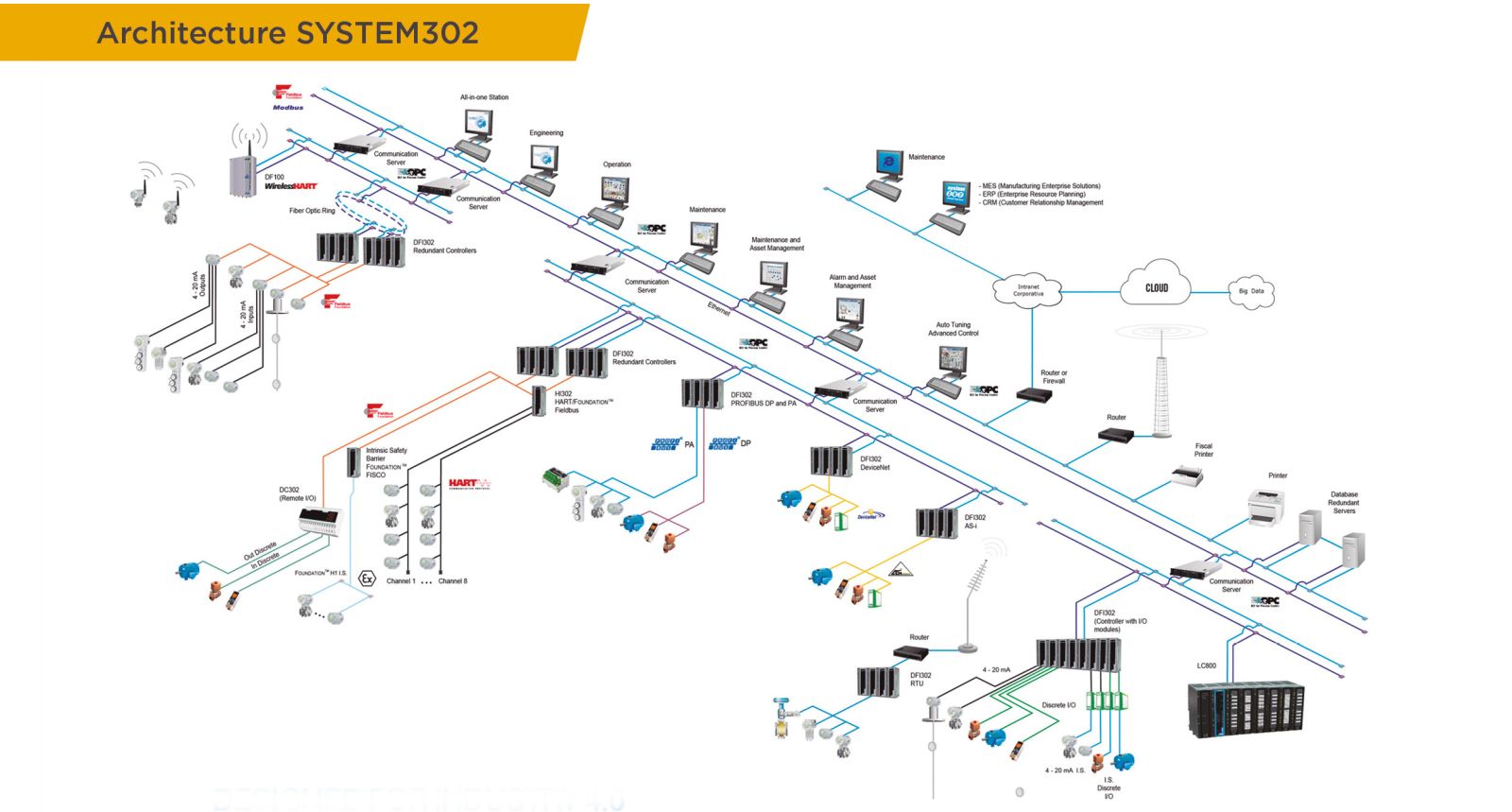

SYSTEM302 is the first hybrid control automation system using digital networks, open and standardized technologies. Each hardware component is visualized as a control element and can participate in the control strategy distributed in the industrial plant.

From June 10 to 14, 2019, in Raleigh, USA, at ISA's premises, Smar participated in the O-PAS interoperability test, along with 17 other automation companies. The tests aimed at validating in January 2019.

This event demonstrates the strength of the OPA Forum, which has led competing companies to unite around the collaborative effort to create superior technology in benefit of their customers.

.jpg)

Engineer Edner Ricardo Pontes / Engineer Delcio Prizon

The central element of the System302 architecture is the DFI (Distributed Field Interface), which performs all functions defined by DCN in the O-PAS architecture. Smar provides these control devices in Foundation Fieldbus, Profibus PA, Profibus DP, Modbus, HART, WirelessHART and conventional signals. Similar to the way we download an applications (APPs) to a smartphone, we can download custom control applications (functional blocks) produced by users through the concept of flexible blocks to the SMAR controllers, making it ready for the next generation of control systems.

User Testimonial

"I am delighted to say that Smar is the best control system provider i have associated with in my 32 years as a Control Systems Engineer. His commitment to Duke Energy and his outstanding service to provide instruments quickly and efficiently are greatly appreciated. I hope to have a long and rewarding association with Smar. I will disclose to all my other associates in the nuclear industry. In short, Smar is absolutely the best." Willard H. Klllough Jr., PE. - Engineer Control Systems.

To learn more, visit the links below:

O-PAS - The Open Group

COPAS - COPA QuickStart™ Showcase

NOVA Product Line - O-PAS Technology